IMT Forge’s manufacturing runs benefit from using advanced simulation software to design tooling. The entire runs are accomplished with minimal rejects, saving man-hours, materials and delays.

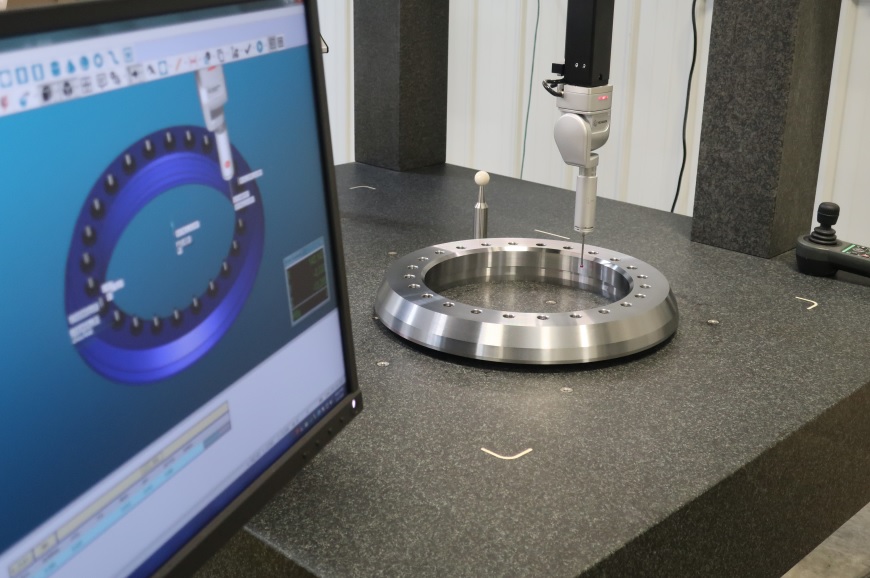

IMT Forge also uses quality-control inspections and statistical process controls to monitor our die forging process, ensuring consistency and quality throughout the production run.

IMT Forge scrutinizes everything from internal process to subcontractor performance to the smallest detail of every product outcome.

We ensure that every part meets our highest standards before being approved for shipment to customers.